This guide condenses the video transcript into a short, actionable tutorial. Follow the steps below to replicate the workflow shown in the video. Applications include eSTOL, STOL and eVTOL aircraft.

Tutorial Steps (from Transcript)

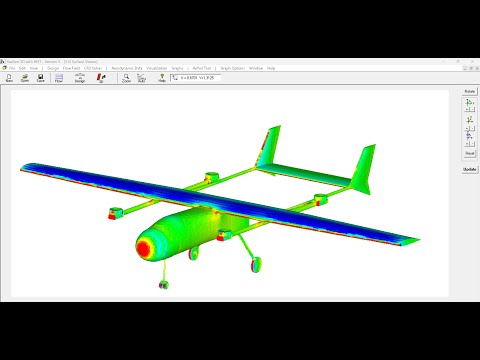

- Hello and welcome to Hanley Innovations. Today we will outline how to set up actuator discs in Stallion 3D to implement a blown wing concept.

- First, we create the wing in Stallion 3D using the built-in geometry tools. This wing has a span dimension of 4 m and a cord of 1 meter.

- It uses a NACA 4412 from the built-in library. Next, we enter the actuator discs parameters.

- For all four, we set a force of 500 Newtons. We copy the first disc and set the Y center to minus 0.75.

- Next, with the same copy, paste a discs with Y centers of 0.25 and minus0.25 respectively to complete the propulsion distribution. Next, set up the CFD using 1 million cubes with the initial X, Y, and Z settings of 2, 2 and two.

- Use the default Navier Stokes solver. Then click the generate grid solve flow menu.

- Stallion 3D will automatically generate the grid and solve the flow. The results show the effects of the disc's prop wash over the wing and in the wake.

- We can now compare the lift force of the unpowered wing to that of the blown wing. The unpowered wing has a lift force of 24 lb in the 20 m/s flow field.

- The blown wing has a lift of 70.8 lb.

- Until next time, thanks for watching.

For more information, please visit https://www.hanleyinnovations.com