Tuesday, January 24, 2017

Avoid Testing Pitfalls

The only way to know if your idea will work is to test it. Rest assured, as a design engineer your idea and designs will be tested over and over again often in front of a crowd of people.

As an aerodynamics design engineer, Stallion 3D helps you to avoid the testing pitfalls that would otherwise keep you awake at night. An advantage of Stallion 3D is it enables you to test your designs on the privacy of your laptop or desktop before your company actually builds a prototype. As someone who uses Stallion 3D for consulting, I find it very exciting to see my designs flying the way they were simulated in the software. Stallion 3D will assure that your creations are airworthy before they are tested in front of a crowd.

I developed Stallion 3D for engineers who have an innate love and aptitude for aerodynamics but who do not want to deal with the hassles of standard CFD programs. Innovative technologies should always take a few steps out of an existing process to make the journey more efficient. Stallion 3D enables you to skip the painful step of grid (mesh) generation. This reduces your workflow to just a few seconds to setup and run a 3D aerodynamics case.

Stallion 3D helps you to avoid the common testing pitfalls.

1. UAV instabilities and takeoff problems

2. Underwhelming range and endurance

3. Pitch-up instabilities

4. Incorrect control surface settings at launch and level flight

5. Not enough propulsive force (thrust) due to excess drag and weight.

Are the results of Stallion 3D accurate? Please visit the following page to see the latest validations.

http://www.hanleyinnovations.com/stallion3d.html

If your have any questions about this article, please call me at (352) 261-3376 or visit http://www.hanleyinnovations.com.

About Patrick Hanley, Ph.D.

Dr. Patrick Hanley is the owner of Hanley Innovations. He received his Ph.D. degree in fluid dynamics for Massachusetts Institute of Technology (MIT) department of Aeronautics and Astronautics (Course XVI). Dr. Hanley is the author of Stallion 3D, MultiSurface Aerodynamics, MultiElement Airfoils, VisualFoil and the booklet Aerodynamics in Plain English.

Sunday, January 15, 2017

Flying Wing UAV: Design and Analysis

3DFoil is a design and analysis software for wings, hydrofoils, sails and other aerodynamic surfaces. It requires a computer running MS Windows 7,8 and 10.

I wrote the 3DFoil software several years ago using a vortex lattice approach. The vortex lattice method in the code is based on vortex rings (as opposed to the horse shoe vortex approach). The vortex ring method allows for wing twist (geometric and aerodynamic) so a designer can fashion the wing for drag reduction and prevent tip stall by optimizing the amount of washout. The approach also allows sweep (backwards & forwards) and multiple dihedral/anhedral angles.

I wrote the 3DFoil software several years ago using a vortex lattice approach. The vortex lattice method in the code is based on vortex rings (as opposed to the horse shoe vortex approach). The vortex ring method allows for wing twist (geometric and aerodynamic) so a designer can fashion the wing for drag reduction and prevent tip stall by optimizing the amount of washout. The approach also allows sweep (backwards & forwards) and multiple dihedral/anhedral angles.

Another feature that I designed into 3DFoil is the capability to predict profile drag and stall. This is done by analyzing the wing cross sections with a linear strength vortex panel method and an ordinary differential equation boundary layer solver. The software utilize the solution of the boundary layer solver to predict the locations of the transition and separation points.

The following video shows how to use 3DFoil to design and analyze a flying wing UAV aircraft. 3DFoil's user interface is based on the multi-surface approach. In this method, the wing is designed using multiple tapered surface where the designer can specify airfoil shapes, sweep, dihedral angles and twist. With this approach, the designer can see the contribution to the lift, drag and moments for each surface. Towards the end of the video, I show how the multi-surface approach is used to design effective winglets by comparing the profile drag and induced drag generated by the winglet surfaces. The video also shows how to find the longitudinal and lateral static stability of the wing.

The following video shows how to use 3DFoil to design and analyze a flying wing UAV aircraft. 3DFoil's user interface is based on the multi-surface approach. In this method, the wing is designed using multiple tapered surface where the designer can specify airfoil shapes, sweep, dihedral angles and twist. With this approach, the designer can see the contribution to the lift, drag and moments for each surface. Towards the end of the video, I show how the multi-surface approach is used to design effective winglets by comparing the profile drag and induced drag generated by the winglet surfaces. The video also shows how to find the longitudinal and lateral static stability of the wing.

The following steps are used to design and analyze the wing in 3DFoil:

1. Input the dimensions and sweep half of the wing (half span)

2. Input the dimensions and sweep of the winglet.

3. Join the winglet and main wing.

4. Generate the full aircraft using the mirror image insert function.

5. Find the lift drag and moments

6. Compute longitudinal and lateral stability

7. Look at the contributions of the surfaces.

8. Verify that the winglets provide drag reduction.

More information about 3DFoil can be found at the following url: http://www.hanleyinnovations.com/3dfoil.html.

About Patrick Hanley, Ph.D.

Dr. Patrick Hanley is the owner of Hanley Innovations. He received his Ph.D. degree in fluid dynamics for Massachusetts Institute of Technology (MIT) department of Aeronautics and Astronautics (Course XVI). Dr. Hanley is the author of Stallion 3D, MultiSurface Aerodynamics, MultiElement Airfoils, VisualFoil and the booklet Aerodynamics in Plain English.

Saturday, January 7, 2017

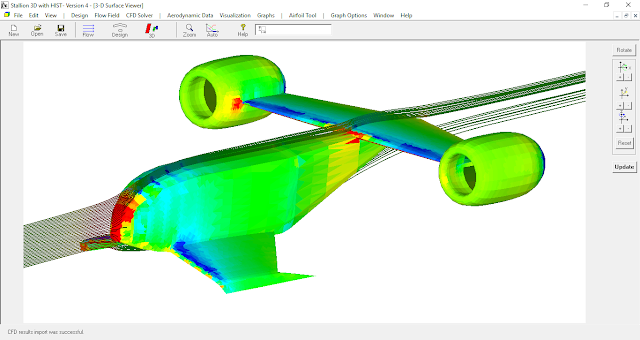

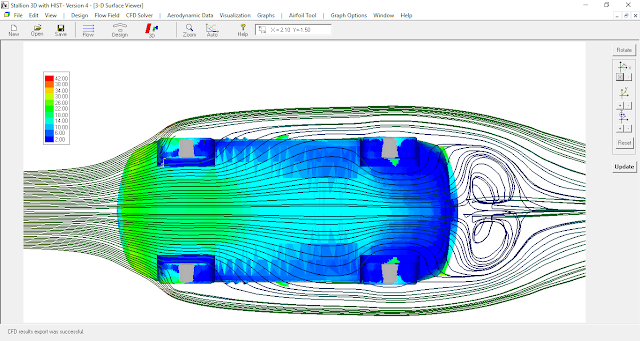

Corvette C7 Aerodynamics

The CAD file for the Corvette C7 aerodynamics study in Stallion 3D version 4 was obtained from Mustafa Asan revision on GrabCAD. The file was converted from the STP format to the STL format required in Stallion 3D using OnShape.com.

Once the Corvette was imported into Stallion 3D, I applied ground effect and a speed of 75 miles per hour at zero angle of attack. The flow setup took just seconds in Stallion 3D and grid generation was completely automatic. The software allows the user to choose a grid size setting and I chose the option the produced a total of 345,552 cells in the computational domain.

I chose the Reynolds Averaged Navier-Stokes (RANS) equations solver for this example. In Stallion 3D, the RANS equations are solve along with the k-e turbulence model. A wall function approach is used at the boundaries.

The results were obtained after 10,950 iterations on a quad core laptop computer running at 2.0 GHz under MS Windows 10.

The results for the Corvette C7 model are summarized below:

Lift Coefficient: 0.227

Friction Drag Coefficient: 0.0124

Pressure Drag Coefficient: 0.413

Total Drag Coefficient: 0.426

Stallion 3D HIST Solver: Reynolds Averaged Navier-Stokes Equations

Turbulence Model: k-e

Number of Cells: 345,552

Grid: Built-in automatic grid generation

Run time: 7 hours

The coefficients were computed based on a frontal area of 2.4 square meters.

The following are images of the same solution from different views in Stallion 3D. The streamlines are all initiated near the ground plane 2 meters ahead of the car.

Top View

Side View

Bottom View

Stallion 3D utilizes a new technology (Hanley Innovations Surface Treatment or HIST) that enables design engineers to quickly analyze their CAD models on an ordinary Window PC. We call this SameDayCFD. This unique technology is my original work and was not derived from any existing software codes. More information about Stallion 3D can be found at:

Do not hesitate to contact us if you have any questions. More information can be found at http://www.hanleyinnovations.com.

Thanks for reading.

About Patrick Hanley, Ph.D.

Dr. Patrick Hanley is the owner of Hanley Innovations. He received his Ph.D. degree in fluid dynamics for Massachusetts Institute of Technology (MIT) department of Aeronautics and Astronautics (Course XVI). Dr. Hanley is the author of Stallion 3D, MultiSurface Aerodynamics, MultiElement Airfoils, VisualFoil and the booklet Aerodynamics in Plain English.

Dr. Patrick Hanley is the owner of Hanley Innovations. He received his Ph.D. degree in fluid dynamics for Massachusetts Institute of Technology (MIT) department of Aeronautics and Astronautics (Course XVI). Dr. Hanley is the author of Stallion 3D, MultiSurface Aerodynamics, MultiElement Airfoils, VisualFoil and the booklet Aerodynamics in Plain English.

Monday, January 2, 2017

Hydrofoil Analysis

For example, let us take a look at a high performance keel. Here, an astute designer might investigate the use of a NACA 6-series airfoil for the cross-sectional shape. The reason for using this airfoil shape for the keel is, of course, the delay in transition from a laminar to turbulent boundary layer along the chord of the airfoil. In an ocean race, this is important because larger regions of laminar flows on the keel produces less overall friction drag or water resistance. Less drag wins races.

But suppose the designer uses the same shape on the rudder, what do you think might happen? A possible side effect of using the 6-series airfoil might be loss of control. Why? The answer has to do with early separation (vs angle of attack) of 6-series airfoils.

Knowing the behavior and use of airfoil shapes in the design of keels, rudders and hydrofoils is one advantage that the best marine designers utilize over their completion. Another, is the importance of three dimensions or 3D in a design. Yes, airfoil behavior is only the first part of a successful aero-hydrodynamic design. The knowledge of the performance of the design in 3-dimensions equips the designer with the exact size (width and length) and shape of winning keels, rudders and hydrofoils.

Anyone can design a keel that is too large (an overwhelming amount of drag) or too small (not effective). However, the subtleties of the best designed planform shape that makes it a winning appendage is a closely held secret that is only divulged by accurate 3-dimensional analysis.

3DFoil/MultiSurface Aerodynamics is based on a novel numerical algorithm that couples the vortex lattice method (based on vortex rings) with a linear strength panel method. Together, these two methods compute accurate values of the lift, drag (both profile and vortex) and moments.

3DFoil buit-it wing design tool makes it very easy for users to accurately design and analyze hydrofoil models. The following video is a tutorial that shows the design and analysis of a L-foil.

3DFoil enables designers to test airfoil shapes, planform designs and stability (longitudinal and lateral). The software is used to rapidly and accurately compute lift, drag, side force and lateral resistance for your designs.

3DFoil is the key to designing the most efficient and effective keels, rudders and hydrofoils. The software has been used over the last decade to train engineering students at the US Coast Guard Academy .

More information and additional videos about 3DFoil can be found at: http://www.hanleyinnovations.com/3dfoil.html

Do not hesitate to contact us if you have any questions.

More information can be found at http://www.hanleyinnovations.com. Thanks for reading.

About Patrick Hanley, Ph.D.

Dr. Patrick Hanley is the owner of Hanley Innovations. He received his Ph.D. degree in fluid dynamics for Massachusetts Institute of Technology (MIT) department of Aeronautics and Astronautics (Course XVI). Dr. Hanley is the author of Stallion 3D, MultiSurface Aerodynamics, MultiElement Airfoils, VisualFoil and the booklet Aerodynamics in Plain English.

Dr. Patrick Hanley is the owner of Hanley Innovations. He received his Ph.D. degree in fluid dynamics for Massachusetts Institute of Technology (MIT) department of Aeronautics and Astronautics (Course XVI). Dr. Hanley is the author of Stallion 3D, MultiSurface Aerodynamics, MultiElement Airfoils, VisualFoil and the booklet Aerodynamics in Plain English.

Subscribe to:

Comments (Atom)